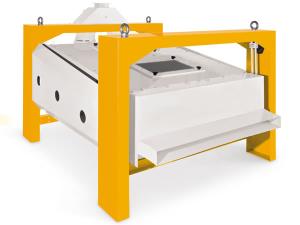

The FQFD series purifier is an indispensable device when manufacturing high-end and low ash content flour. It is used to purify and grade the different-sized middling and semolina offered by the previous plansifter for a second time, thus obtaining pure middling and semolina with improved quality and more consistent particle size distribution. Subsequently, these high-quality intermediate products will enhance the flour quality.

1. Low Maintenance Cost

The machine components are very robust, and the service cycle is quite long. So, the maintenance cost is effectively cut down.

2. High Processing Capacity

With three sieve decks and a net sieve width of 460mm, our purifier exhibits better processing capacity when compared with similar machines. Technically speaking, the throughput of every single machine could reach up to 3t/h.

3. Top-Ranking End Product

The materials are conveyed at a constant speed to pass the feed gate, and then they are evenly distributed on the sieve. So, continuous production is realized, and the final product’s quality is ensured. On the other hand, the sieves are cleaned in a reliable way, and this means consistent product quality is expectable.

4. Perfect Sanitation

The metal sieve frame is outfitted with a brush cleaner to avoid material accumulation, so our machine will be very clean. Meanwhile, the optimized aspiration system ensures that there will be no residues, thereby realizing sanitary operation.

5. Scientific Design

Our purifier is meticulously designed and fabricated according to actual applications. The maintenance-free transmission device has no lubrication points, so the maintenance cost is reduced. There are lighting devices inside the machine, and this offers possibility to monitor the whole operation process, from material feeding to sifting.

Reviews

There are no reviews yet.